Our vision is to simplify manufacturing complexities and shorten project cycles for our customers through our rich manufacturing and design experience. Our success is defined by our customers' success

Quick Links

Our Injection Molding Services

High-quality steel tooling, quick lead times, and no minimum order requirements — perfect for prototyping, validating designs, and bridge production needs

Whether it's buttons, grips, or seals, enhance your existing plastic parts by molding rubber or silicone over them for improved functionality and durability

Encase a preformed, frequently metal-threaded insert with molded plastic for integrated assembly

0t-0t

Injection Molding Machine

0pc

MOQ

0.00mm

Mold Tolerance

0 Weeks

T1 Sample

91MNS Injection Molding Solutions

Rapid Prototyping

Meet crucial time-to-market demands by offering flexibility and cost-effective solutions for iterative development before full-scale production.

High-Volume Production

Meet the demands of large-scale manufacturing by effectively addressing common production challenges and providing on-demand production capabilities.

Employ aluminum or steel molds, ideal for rigorous testing and iterative procedures.

Robust steel molds engineered for exceptional repeatability throughout extensive production cycles, ensuring longevity and consistency.

These molds are typically single cavity, enabling precise control in the prototype stage.

Offered in single or multi-cavity setups to enhance efficiency and cost-effectiveness, tailored to suit diverse production needs.

Easily manufacture anything from individual units to small batches, facilitating rapid market testing and design validation.

Seamlessly scale production to accommodate high-volume orders, maintaining unwavering quality standards and meeting delivery deadlines with precision.

Injection Molding Materials

ABS

Types: /

Properties:

ABS is strong, durable, and offers good resistance to heat and impact. It’s preferred for automotive components and consumer goods.

Acrylic/PMMA

Types: /

Properties:

PMMA, or acrylic, is known for its crystal clarity and weather resistance, making it ideal for outdoor fixtures and display cases.

POM(Delrin)

Types: 150, AF (13% PTFE Filled), 30% Glass Filled

Properties:

POM is strong, with a low friction surface and good dimensional stability, perfect for precision parts in mechanical applications.

PE

Types: /

Properties:

HDPE is known for its high strength-to-density ratio, resistance to impacts, and is used in making bottles and corrosion-resistant piping.

HDPE

Types: /

Properties:

HDPE is known for its high strength-to-density ratio, and resistance to impacts, and is used in making bottles and corrosion-resistant piping.

PA(Nylon)

Types: PA(Nylon) PA6 (Nylon)+GF15 PA6 (Nylon)+GF30 PA66

Properties:

Nylon is versatile, strong, and wears well against friction, commonly used for gears, bearings, and other wear-resistant surfaces.

HIPS

Types: /

Properties:

HIPS is easy to machine and offers good dimensional stability and impact resistance, suitable for prototyping and modeling.

PEEK

Types: /

Properties:

PEEK is renowned for its high temperature resistance and strength, often used in aerospace and medical implant manufacturing.

Polycarbonate

Types: /

Properties:

Polycarbonate is extremely durable and has high impact resistance, along with excellent clarity, used for bullet-proof glass and protective gear.

Polypropylene

Types: /

Properties:

Polypropylene is tough, has excellent chemical resistance, and is used for automotive parts, containers, and in packaging.

PTFE

Types: /

Properties:

PTFE is known for its outstanding chemical resistance and low friction, making it perfect for non-stick coatings and gaskets.

UPE

Types: /

Properties:

UPE has extremely long chains, resulting in a very tough material, ideal for high-abrasion applications like lining chutes.

LDPE

Types: /

Properties:

LDPE is soft, flexible, and used in applications where heat sealing is required, such as in tubing and plastic bags.

PBT

Types: /

Properties:

PBT is a strong, rigid plastic that is heat resistant and commonly used in electrical components and casings.

PPA

Types: /

Properties:

PPA offers high heat resistance and stiffness, ideal for automotive and electrical applications that require durability at high temperatures.

PAI

Types: /

Properties:

PAI has exceptional thermal and chemical stability, used in high-performance parts in aerospace and automotive sectors.

PET

Types: /

Properties:

PET is strong, resistant to moisture and chemicals, and widely used in food containers and textile fibers.

PPS

Types: /

Properties:

PPS features outstanding chemical and heat resistance, suitable for automotive and aerospace components.

PS

Types: /

Properties:

Polystyrene is lightweight and easy to machine, used for models, prototypes, and low-strength applications.

PVC

Types: /

Properties:

PVC is robust, cheap, and has good chemical resistance, used in plumbing, medical devices, and cables.

Bakelite

Types: /

Properties:

Bakelite is heat resistant and electrically non-conductive, perfect for electrical insulators and radio and telephone casings.

FR-4

Types: /

Properties:

FR-4 is a flame-resistant material, primarily used in the electronics industry for circuit boards and insulators.

Injection Mold Surface Finishes

All finishes meet SPI standards

Heat plastic to reshape it and embed a component such as a threaded insert for enhanced functionality and structural integrity.

Engraving text or a logo with a laser.

Using an ink-based, 2D design to a flat/3D surface

Utilizing primer, top coat paint application in a variety of standard and Pantone colors for a comprehensive finishing solution

Connect or reshape thermoplastics using a high-frequency welder for precision bonding and structural modifications

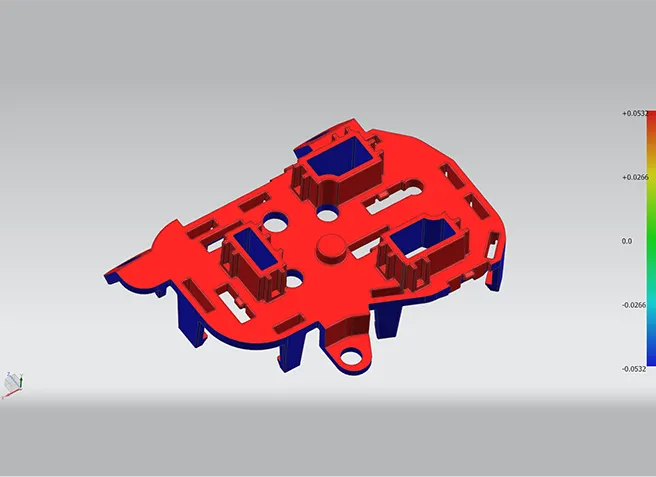

Professional DFM Analysis Services: Optimizing Designs, Lowering Costs

In the manufacturing process, design plays a crucial role in product quality and production efficiency. We offer professional Design for Manufacturability (DFM) analysis services to ensure your design can smoothly transition to the production phase, reducing production issues and costs.

Service Highlights:

Undercut Analysis: Identify and optimize undercut designs to ensure smooth material flow, avoiding bubbles and defects.

Draft and Slider Consideration: Professional analysis of draft angles and sliders to ensure smooth mold opening and closing, preventing sticking and damage.

Shrinkage Analysis and Recommendations: Detailed analysis of shrinkage effects, offering insights to optimize designs and minimize dimensional variations, ultimately reducing costs.

Cost Analysis and Recommendations: Provide detailed cost analysis, identify potential cost-saving opportunities, and offer reasonable suggestions and optimization solutions.

Why Choose Us:

Professional Team: Our experienced team of engineers focuses on DFM analysis and optimization.

Efficient Service: We respond quickly to your needs, providing fast and accurate analysis results.

Customized Recommendations: We offer personalized suggestions and solutions based on your requirements and needs.

Let us help you optimize your design, improve production efficiency, and reduce costs. Contact us to learn more about our DFM analysis services.

Injection Molding FAQs

Q What is injection molding and how does it work?

Injection molding is a manufacturing process where molten material is injected into a mold cavity, cooled, and solidified to produce a desired part shape. It is commonly used for mass production of plastic components.

Q What types of products are typically made using injection molding?

Injection molding is used to manufacture a wide range of products, including automotive parts, consumer goods, medical devices, electronics components, and packaging materials.

Q What are the advantages of using injection molding for manufacturing?

Injection molding offers advantages such as high production speed, cost-effectiveness for large production runs, design flexibility, precise part replication, and the ability to use a variety of materials.

Q What factors affect the quality of injection molded parts?

The quality of injection molded parts can be influenced by factors like mold design, material selection, processing parameters, tooling maintenance, and quality control measures during production.

Q What is the typical lead time for an injection molding project?

The lead time for an injection molding project can vary depending on factors such as part complexity, mold design, material availability, and production volume. It can range from a few weeks to several months.

Q How can defects in injection molded parts be minimized?

Minimizing defects in injection molded parts involves optimizing processing parameters, ensuring proper mold design and maintenance, conducting thorough quality inspections, and implementing corrective actions as needed.

Talk to Us About Your New Project!

Get a Quote